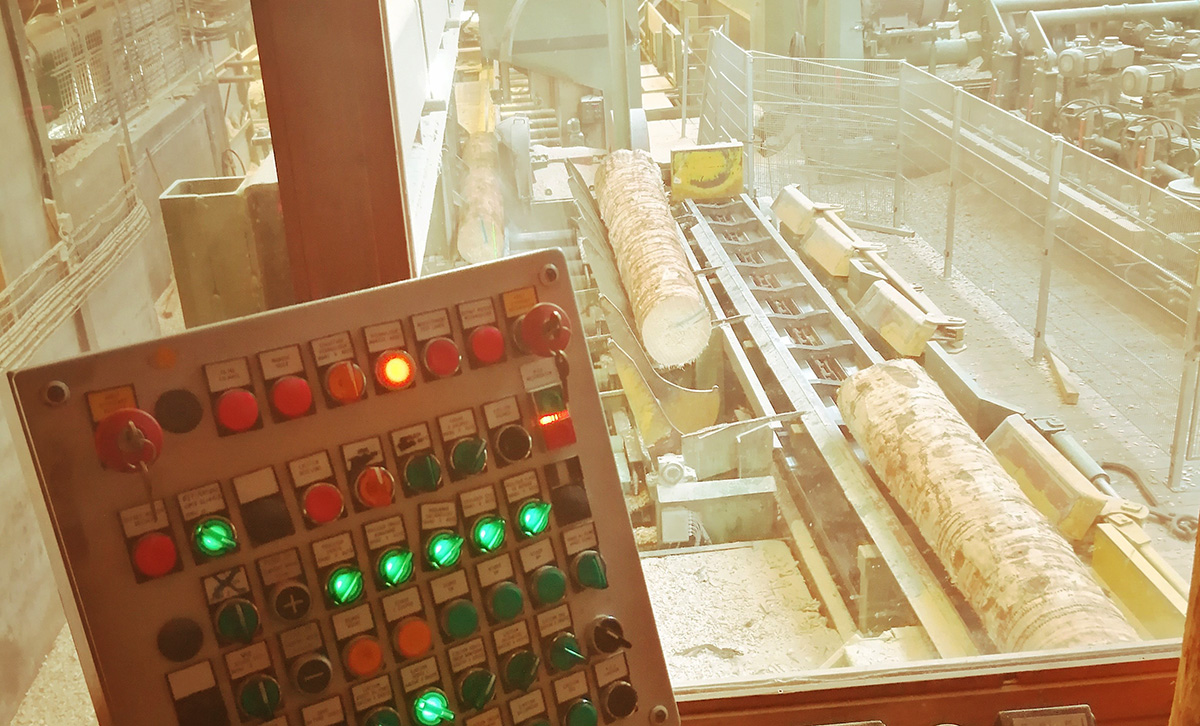

Logyard and gantry crane

The gantry is the first step in the production chain. It manages the arrival of tree trunks (logs) and organises them in our logyard. Next, our cross-cutting station is fully computerised with a butt-end reducer and a debarking zone.

Log saw

Our bandsaw composed of a slabber allows us to work long lengths up to 12 metres and cut-to-size measurements.

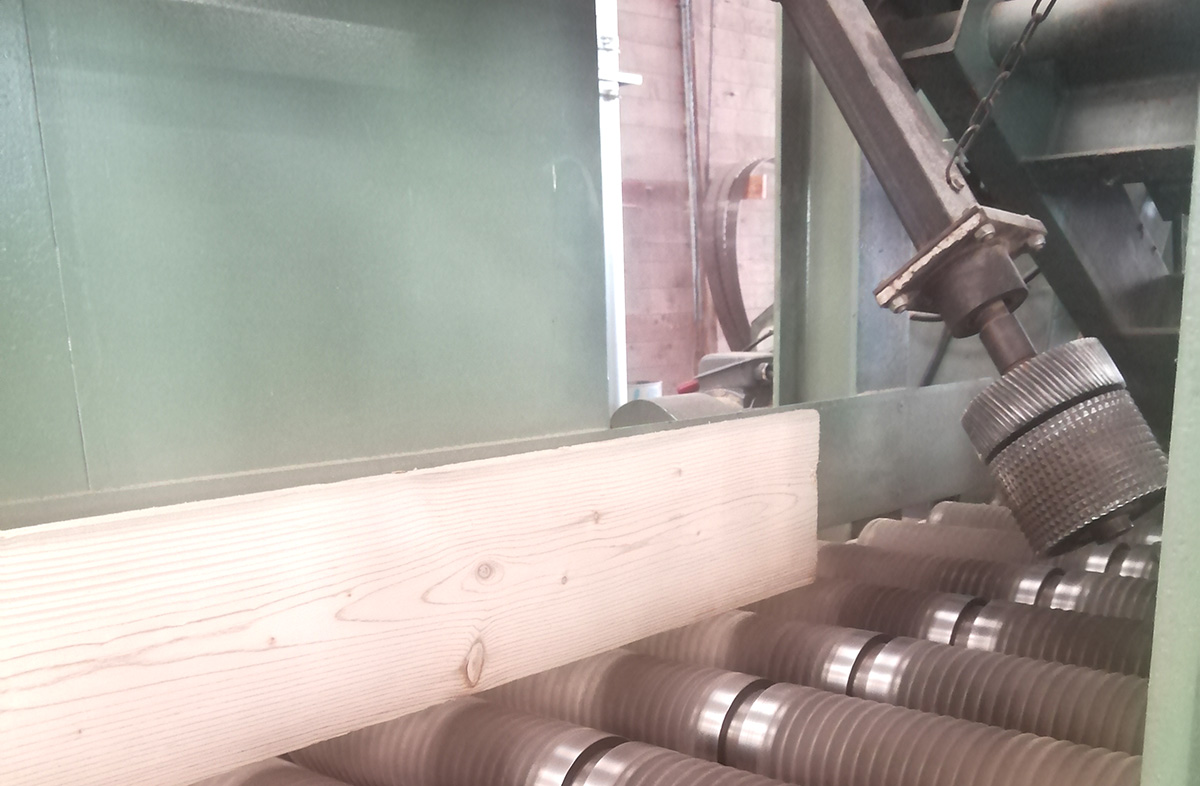

Edger

This tool allows us to saw a piece of wood while respecting the direction of the wood fibres in order to maintain optimal quality.

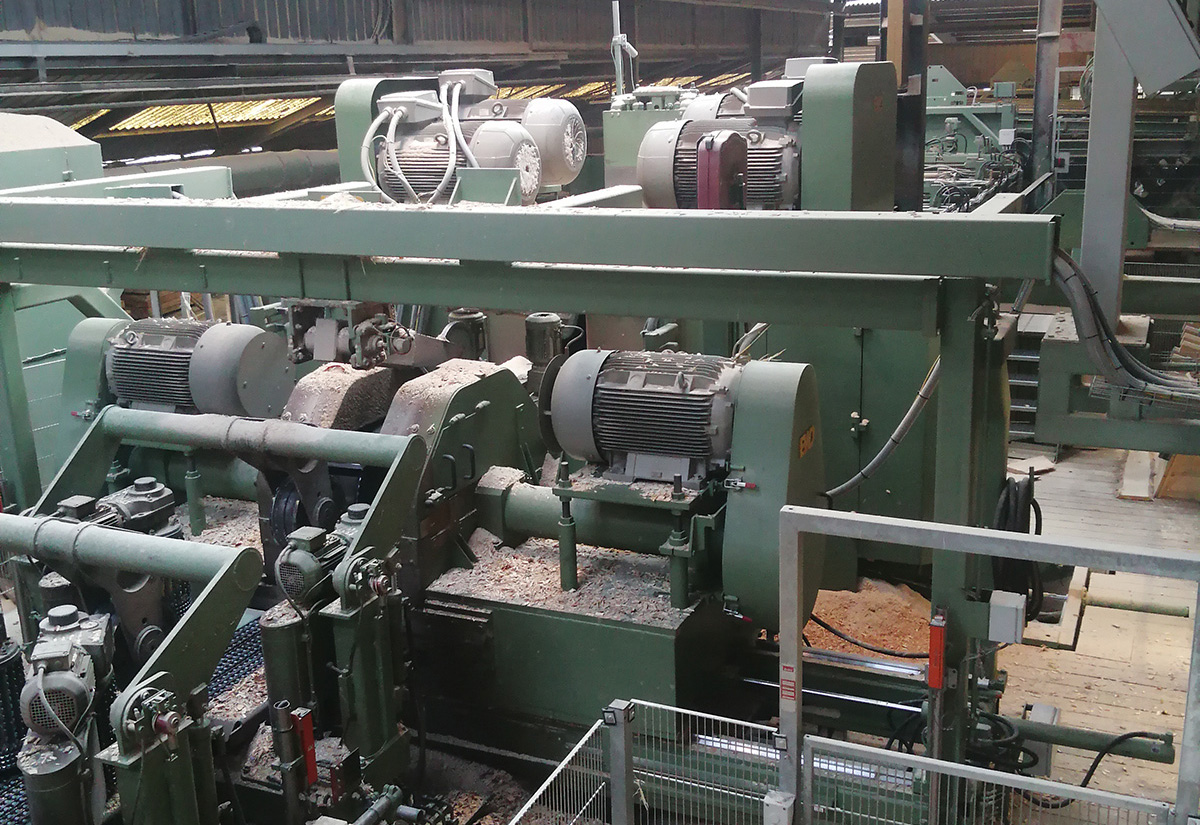

Chipper canter

With several moving blades, our chipper canter is able to saw with very high precision diameters ranging from 180 to 450mm, and lengths from 2.5 to 7 metres.

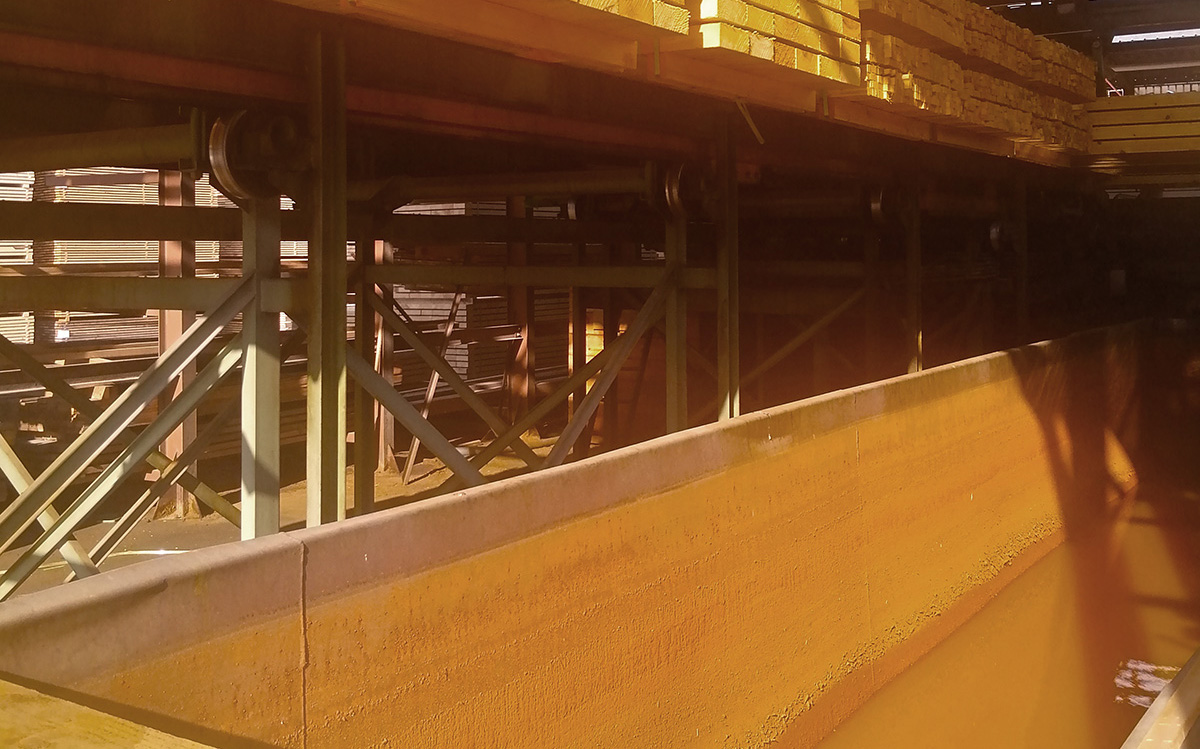

Sorter

Our equipment sorts sawn timber without human intervention, taking into account the lengths, dimensions and quality of the wood. They are then transferred to the automatic stacking station.

Xylophène Treatment

Our two automated dip tanks treat the timber. It also brushes the wood in order to bring out the grain and give the product dimension.

Dryers/span>

With 180 m3 of traditional drying and 15 m3 of vacuum drying, we treat wood for use in construction and packaging (ISPM 15).

Planing line

Our planing line gives raw wood a smooth and straight finish. It also brushes the wood in order to bring out the grain and give the product dimension.

Round rod machine

This machine planes wood with a diameter of 140 to 400mm along the profile to make it cylindrical.

K2 Machining Centre

This computer numerical control (CNC) computer-aided machining centre allows us to create all types of wooden items. It machines all lengths on dimensions from 20 x 50mm to 300 x 450mm without measuring and without marking out.

Logyard and gantry crane

The gantry is the first step in the production chain. It manages the arrival of tree trunks (logs) and organises them in our logyard. Next, our cross-cutting station is fully computerised with a butt-end reducer and a debarking zone.

Chipper canter

With several moving blades, our chipper canter is able to saw with very high precision diameters ranging from 180 to 450mm, and lengths from 2.5 to 7 metres.

Log saw

Our bandsaw composed of a slabber allows us to work long lengths up to 12 metres and cut-to-size measurements.

Sorter

Our equipment sorts sawn timber without human intervention, taking into account the lengths, dimensions and quality of the wood.

Xylophène Treatment

Our two automated dip tanks treat the timber. The processing, dip and draining times follow strict guidelines, guaranteeing quality and respect for the environment.

Planing line

Our planing line gives raw wood a smooth and straight finish. It also brushes the wood in order to bring out the grain and give the product dimension.

Dryers

With 180 m3 of traditional drying and 15 m3 of vacuum drying, we treat wood for use in construction and packaging (ISPM 15).

Round rod machine

This machine planes wood with a diameter of 140 to 400mm along the profile to make it cylindrical.

K2 Machining Centre

This computer numerical control (CNC) computer-aided machining centre allows us to create all types of wooden items. It machines all lengths on dimensions from 20 x 50mm to 300 x 450mm without measuring and without marking out.

Edger

This tool allows us to saw a piece of wood while respecting the direction of the wood fibres in order to maintain optimal quality.